Mar 23, 2023 | Blog

The development and production of ultraviolet (UV) coated medical devices are complex processes that require precision, accuracy, and adherence to strict regulatory standards. As the demand for advanced medical devices continues to grow, manufacturers seek reliable and efficient solutions to streamline the UV light curing coating process and maintain the highest level of quality. Uvitron’s power supplies play an essential role in facilitating the UV light curing of medical devices, ensuring consistent and robust performance throughout the entire process.

Medical devices that require UV light curing include catheters, stents, and implantable devices such as pacemakers and artificial joints. UV light curing is a process that involves the use of ultraviolet light to cure a thin layer of coating material onto the surface of the medical device. This coating provides a protective layer that can reduce the risk of infection, prevent corrosion, and improve the biocompatibility of the device.

The Crucial Role of Power Supplies in the Medical Device Coating Process

Consistent and Precise Energy Delivery

A stable and reliable power supply is crucial for maintaining the integrity and performance of the medical device coating process. Uvitron’s power supplies provide consistent energy delivery, ensuring that UV light curing systems can achieve the desired thickness and uniformity of the applied coatings. This level of precision is essential for meeting the stringent requirements of the medical industry, where variations in coating thickness can significantly impact device performance and safety.

Optimized Efficiency for Reduced Downtime

Efficient power supplies minimize energy waste and reduce the overall cost of production. Uvitron’s power supplies are designed to optimize energy usage, ensuring that UV light curing equipment operates at peak efficiency. By reducing downtime and lowering energy consumption, Uvitron’s power supplies help manufacturers maintain a lean and cost-effective production process.

Ensuring Safe and Reliable UV Light Curing

Medical device coatings must meet stringent regulatory standards to ensure safety, efficacy and biocompatibility. These standards encompass a variety of criteria, including electrical safety and performance specifications. Uvitron’s power supplies are engineered to reliably maintain these material safety properties throughout the curing process.

Scalability and Adaptability

As medical device manufacturers continue to innovate and explore new UV light curing technologies, power supplies must be capable of adapting to evolving needs. Uvitron’s power supplies offer scalability and flexibility, allowing manufacturers to integrate them into UV light curing systems with varying power requirements and configurations. This adaptability ensures that power supplies can accommodate emerging technologies and advancements in the medical device coating industry.

Advantages of Uvitron’s UV Arc Lamp Power Supplies for Medical Device Coating Process

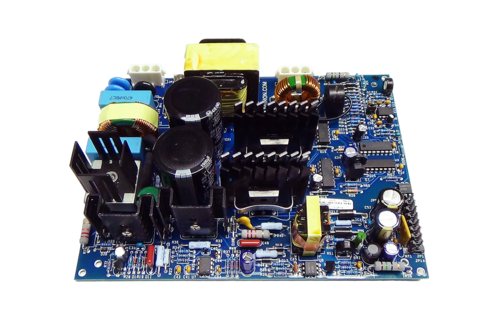

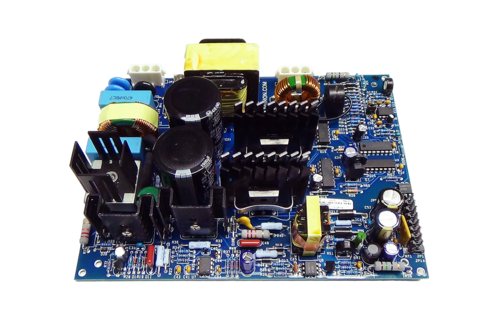

In the medical device coating process, having reliable and precise UV light curing is crucial. That’s where Uvitron’s UV arc lamp power supplies come in, empowering this critical stage of the process. These power supplies utilize cutting-edge high-frequency, solid-state, switch-mode technology, resulting in incredibly compact and lightweight units with tight output power regulation.

What’s more, Uvitron’s power supplies offer constant UV lamp power, ensuring repeatable cure times and long lamp life, even when faced with fluctuations in AC input or lamp voltages. This level of consistency and reliability is essential in achieving the desired results and ensuring product quality. With Uvitron’s power supplies, medical device manufacturers can have peace of mind knowing their UV light curing process is in good hands.

Full Featured Arc Lamp Power Supply

Discover the power and convenience of our full-featured arc lamp power supply, designed to deliver a constant power source for 400W, 600W, and 800W UV halide or other ultraviolet-emitting lamps. This innovative power supply is perfect for businesses operating in multiple countries, thanks to its auto-ranging AC input that eliminates the need for voltage selectors or rewiring when used internationally.

The lamp power regulation feature ensures consistent curing times by automatically adjusting the current reference to compensate for variations in lamp and line voltage. This means you’ll achieve reliable results even as the lamp ages, when it’s replaced, or when the input voltage fluctuates.

Additionally, our arc lamp power supply boasts a standby power mode that reduces UV arc lamp power to 1/2 for 400W and 1/3 for 600W, decreasing excess heat and power consumption during idle periods. This not only increases system reliability and efficiency but also reduces ambient temperature rise, making it an ideal choice for businesses looking to optimize their UV-curing processes.

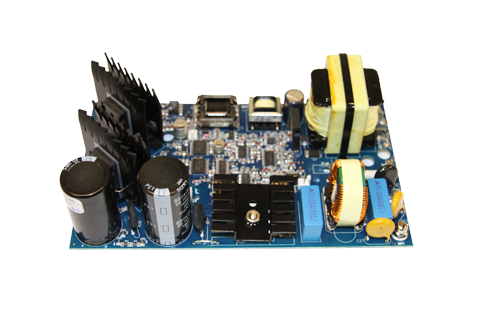

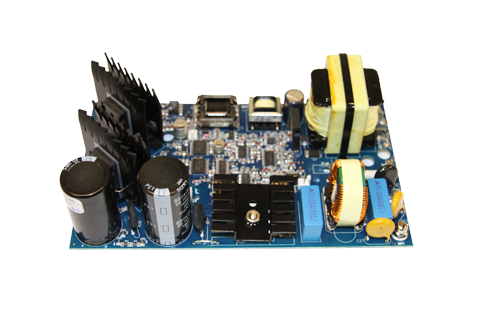

Economical Arc Lamp Power Supply

Upgrade your UV-curing system with our economical arc lamp power supply, a compact switch-mode power source designed to deliver constant power to 400W and 600W mercury vapor bulbs or medium pressure metal halide arc lamps. This versatile power supply is available in both 100/120AC and 200/240AC versions to accommodate international use, making it an ideal choice for businesses operating in multiple countries.

Our economical arc lamp power supply features a standby switch signal, reducing lamp output power to 1/2 for 400W and 1/3 for 600W during idle periods. This helps to minimize excess heat and power consumption, improving system reliability and efficiency while reducing ambient temperature rise. Additionally, the power supply includes an un-isolated 12V output for powering a local cooling fan and an integrated lamp igniter, eliminating the need for an external high-voltage starter.

With two input voltage range options, an integrated high-voltage lamp starter, and lamp power regulation for consistent curing times, our economical arc lamp power supply ensures reliable performance even as the lamp ages or when the input voltage fluctuates. The power supply also features a ready LED indicator, providing a visual cue when the lamp warm-up is complete.

HiWatt 2: Programmable Electronic Arc Lamp Ballast

Upgrade your UV-curing system with our HiWatt 2 programmable electronic arc lamp ballast, a dual-processor controlled, solid-state switching power supply designed for ultimate adaptability and performance. This innovative ballast is factory or customer software configurable via a PC serial port, allowing it to power a wide range of lamp types and utility power sources, making it a truly universal solution for various lamps and power sources worldwide.

The HiWatt 2 ballast is capable of powering arc lamps in the range of 1kW–20kW, with lamp voltages of 200–850V, from single or three-phase AC sources. It can even power two arc lamps in a series, as long as the total composite voltage does not exceed 850V. This versatility sets the HiWatt 2 apart as a single-unit solution for many types of lamps and applications.

Communication with customer-connected controllers or PCs is seamless via optically isolated digital logic signals, RS485 serial port, or USB port. This connectivity enables monitoring and control of lamp enable/disable, lamp dimming, and lamp cooling blower control. The HiWatt 2 can also optionally control motorized or pneumatic lamp shutters for added functionality.

In the intricate process of UV coating medical devices, reliable and efficient power supplies are indispensable. Uvitron’s power supplies play a critical role in facilitating the UV coating process, offering consistent energy delivery, optimized efficiency, regulatory compliance, and adaptability to emerging technologies. By providing solutions that streamline and enhance the medical device coating process, Uvitron is proud to contribute to the development of advanced, high-quality medical equipment that improves patient care and outcomes.

Mar 15, 2023 | Blog

The pharmaceutical and biotech industries have always been at the forefront of technological innovation, constantly exploring advanced solutions to optimize their manufacturing processes and enhance product quality. One such technology that has gained significant attention in recent years is UV curing.

UV curing is a cutting-edge photochemical process that utilizes ultraviolet light to initiate the curing or drying of coatings, adhesives, and inks. This technology offers a multitude of advantages, including rapid curing time, low energy consumption, and improved product durability. For the pharmaceutical and biotech industries, UV curing systems are increasingly regarded as an essential tool for streamlining production processes and ensuring high product quality.

UV curing systems are being used in the pharmaceutical and biotech industries for various applications, including drug encapsulation and coatings, medical device production, and more. UV curing systems offer several benefits to the pharmaceutical and biotech industries, making them an essential tool for manufacturing processes. These benefits include:

Rapid Curing Time

UV curing systems offer a significantly faster curing time compared to traditional curing methods. This results in reduced production time, lower labor costs, and decreased risk of product contamination. The rapid curing time allows for streamlined and efficient production, which is essential for the pharmaceutical and biotech industries that need to produce large volumes of products in a short time.

Improved Product Quality

UV curing technology enhances the resistance of coatings and adhesives to environmental factors and chemical degradation, resulting in superior product durability. This technology is instrumental in ensuring consistent drug efficacy, stability, and shelf life. Additionally, it allows for greater precision in the application of coatings, ensuring even and consistent coverage. This is important for the pharmaceutical and biotech industries that require high-quality products that meet strict regulatory standards.

Increased Flexibility in Manufacturing

UV curing systems are incredibly versatile, lending themselves to various applications, including drug encapsulation and coatings, medical device production, and more. This versatility translates to greater flexibility in manufacturing processes, allowing for streamlined and efficient production. Additionally, it enables the development of new products, such as implantable medical devices, that require precise and durable coatings.

Eco-Friendliness

UV curing technology is highly sustainable, with low energy consumption resulting in significantly reduced environmental impact. It provides an eco-friendly solution for drug and treatment manufacturing, supporting the biotech and pharma industries’ drive towards more sustainable production processes and reducing the carbon footprint of pharmaceutical manufacturing.

Uvitron

Uvitron is a leading manufacturer of UV curing systems that are designed to meet the diverse needs of various industries, including pharmaceutical and biotech. With state-of-the-art technology and commitment to quality, Uvitron has become a trusted partner for many companies in the pharmaceutical and biotech industries. Let’s take a look at a few of the UV Curing systems that Uvitron offers:

Uvitron IntelliRay

Introducing the IntelliRay, a revolutionary UV flood curing system that’s compact and programmable. Designed with microprocessor-controlled technology, all system components are integrated into a small lamp head, making it easy to mount on the optional Rayven benchtop curing chamber or anywhere on a factory floor, without requiring cabling or remote power boxes. Simply connect the AC line cord, mount the head and start timed exposure curing.

The system comes with an integrated retractable shade type shutter, which not only allows for repeatable exposure timing but also shields the user from harmful UV rays. Additionally, the system’s LCD display and digital keypad make programming and monitoring of curing operations a breeze. With its long-life arc lamp and parabolic reflector, the IntelliRay provides even illumination of an 8 x 6″ curing area. The arc lamp is powered by the state-of-the-art UV Power-Plus Lamp Driver. The head also features a convenient carrying handle and a sliding height adjustment bracket.

Choose between the 400W or higher intensity 600W version of the Uvitron IntelliRay for your UV curing needs. For larger-scale projects, check out the IntelliRay Quad. Experience hassle-free, precision UV curing with the IntelliRay – order yours today!

Uvitron IntelliRay Quad

Introducing the IntelliRay Quad, a large area, programmable UV flood curing system that’s perfect for tackling big projects. With all system components integrated into a single unit, it’s easy to mount on the optional Rayven Quad benchtop UV curing chamber or anywhere on a factory floor without requiring cabling or remote power boxes. Simply connect the AC line cord, mount the lamp head, and start timed exposure curing.

The system features an integrated retractable shade type shutter, allowing for repeatable exposure timing and providing protection from harmful UV rays. Programming and monitoring of curing operations is a breeze thanks to the system’s LCD display and digital keypad. The four long-life arc lamps and parabolic reflectors deliver even illumination across a 16 x 12″ curing area. The arc lamps are powered by the state-of-the-art UV Power-Plus Lamp Driver.

Upgrade your UV curing game with the IntelliRay Quad – order now for hassle-free, precision curing.

You’re moments away from securing your UV Curing System!

At Uvitron, we make it easy for our customers to get in touch with us. We offer a live chat feature on our website, which allows you to connect with a member of our team in real-time to get answers to your questions. Alternatively, you can fill out our contact form, and one of our representatives will get back to you as soon as possible.

If you’re looking for a customized UV light curing system, you can request a quote directly through our website. Our easy-to-use configurator tool allows you to select the options that best fit your needs, and our team will provide you with a personalized quote based on your selections.

Of course, if you prefer to speak with us directly, you can always give us a call at +1 (413) 731-7835 or send us an email at info@uvitron.com. Our team is always ready to help you find the right UV curing solution for your application.

Thank you for considering Uvitron for your UV curing needs!

Contact Information

Phone number: +1 (413) 731-7835

Fax: (413) 731-7767

Email: info@uvitron.com

Uvitron International, Inc. 150 Front Street, Unit 4 West Springfield, Massachusetts 01089

Mar 12, 2023 | Blog

If you have ever had a cavity filled or orthodontic braces put on, you might have experienced the wonders of

UV light curing in the dental industry. This technology is a game-changer in the field of dentistry, making it easier, faster, and more precise to cure dental materials such as resins, adhesives, and composites.

Dental Composites

Dental composites are a popular alternative to traditional silver amalgam fillings. Unlike amalgam fillings, which are made of a mixture of metals and can sometimes be visible when you smile, dental composites are made of tooth-colored materials, making them more aesthetically pleasing. When a dentist applies dental composite to a cavity or damaged tooth, they first remove the decay or damaged part of the tooth and then apply the composite resin in layers. Each layer is carefully shaped and hardened using the high-intensity UV light, which provides precise control over the curing process.

The use of UV light curing in dental composites provides several benefits. First, it is a quick and efficient way to cure the composite material. The light can be focused on the exact area that needs to be cured, ensuring that the material hardens evenly and accurately. This helps to reduce the amount of time that a patient needs to spend in the dentist’s chair. Second, UV light curing provides a strong bond between the composite material and the tooth. When the composite is exposed to the UV light, it initiates a chemical reaction that causes the material to harden and bond to the tooth’s surface. This bond provides a tight seal that prevents bacteria from entering the tooth and causing further decay. Finally, dental composites that are cured using UV light are highly durable and long-lasting. The materials used in dental composites are designed to mimic the natural strength and resilience of teeth, making them an excellent choice for restoring damaged teeth.

Orthodontic Brackets

Orthodontic treatment is used to correct misaligned teeth and jaws, and one of the most common tools used in this type of treatment is braces. Braces consist of brackets that are attached to the teeth using adhesive, and wires that are used to apply pressure to the teeth and move them into the correct position.

To ensure that the brackets remain securely attached to the teeth throughout the course of treatment, it is crucial to use a strong adhesive that creates a durable bond between the bracket and the tooth. This is where UV light curing comes in. After the orthodontist has applied the adhesive to the bracket and positioned it on the tooth, they use a UV light to initiate the polymerization process. This process causes the adhesive to harden and bond to the tooth’s surface, creating a strong and durable bond between the bracket and the tooth. UV light curing is a quick and efficient way to initiate the polymerization process, which means that the adhesive cures rapidly, reducing the time that the patient needs to spend in the dental chair. It also provides a more reliable bond than traditional adhesives, which may not cure completely or may not bond as strongly to the tooth’s surface.

A strong bond between the bracket and the tooth is essential for the success of orthodontic treatment. The bracket needs to stay securely attached to the tooth throughout the course of treatment to ensure that the right amount of pressure is applied to the tooth to move it into the correct position. A weak bond can lead to the bracket coming loose or falling off, which can delay treatment and cause discomfort for the patient.

Dental Prosthetics

UV light curing is also used in the fabrication of dental prosthetics such as dentures and crowns. Dental prosthetics such as dentures and crowns are used to replace missing or damaged teeth. They are typically made using a resin-based material that is molded to the shape of the patient’s mouth. Once the prosthetic is shaped and positioned correctly, it is cured using UV light.

The use of UV light curing in the fabrication of dental prosthetics provides several benefits. First, it ensures that the material hardens quickly and evenly, which is critical for achieving a perfect fit. This is particularly important for dental prosthetics, which need to fit snugly and comfortably in the patient’s mouth to function correctly. Second, UV light curing provides a strong and durable prosthetic that can withstand the wear and tear of daily use. The material used in dental prosthetics is designed to mimic the strength and resilience of natural teeth, and the use of UV light ensures that the material cures properly, providing a prosthetic that can last for many years. Finally, UV light curing is a precise and efficient way to fabricate dental prosthetics. It allows dentists to create custom-made prosthetics that fit the patient’s mouth perfectly, without the need for multiple adjustments or fittings.

Teeth Whitening

Teeth whitening is a cosmetic dental procedure that has become increasingly popular in recent years. It involves the use of a whitening agent, such as hydrogen peroxide or carbamide peroxide, to remove stains and discoloration from the teeth. Traditionally, teeth whitening agents were applied to the teeth and left to sit for a period of time. However, this process could be slow and inefficient, and patients often had to undergo multiple sessions to achieve the desired results. With the advent of UV light curing, teeth whitening has become a much more efficient and effective process.

UV light is used to accelerate the chemical reaction between the whitening agent and the tooth surface, resulting in a more rapid and thorough whitening process. The UV light activates the whitening agent, causing it to break down and release oxygen molecules, which then penetrate the tooth enamel and break down the molecules responsible for staining and discoloration. The use of UV light curing in teeth whitening provides several benefits. First, it is a safe and effective way to achieve whiter teeth. Unlike some other whitening methods, UV light curing does not damage the tooth enamel or cause sensitivity. Second, it is a fast and efficient process. Patients can typically achieve noticeable results after just one session, which makes it an ideal option for those with busy schedules or special events coming up. Finally, UV light curing ensures that the whitening agent is evenly distributed across the tooth surface, which results in a more uniform and natural-looking whitening effect.

UV light curing has become an indispensable tool in the dental industry, providing an efficient, fast, and accurate way to cure dental materials. Its versatility has made it a valuable asset in a variety of dental applications, from bonding and filling to prosthetics and teeth whitening. With ongoing research and development, it is likely that UV light curing will continue to play a vital role in the dental industry for years to come.

_______________________

This article is intended solely for educational purposes and is not a substitute for professional dental advice. It explores the benefits and applications of UV light curing technology in dentistry, including its use in dental composites, orthodontic brackets, dental prosthetics, and teeth whitening. While providing an overview of how UV light enhances the efficiency and outcomes of dental treatments, it’s important to consult with a qualified healthcare provider for personalized advice or treatment related to dental health. Uvitron International Inc., mentioned herein, does not engage in the dental industry nor endorse specific dental procedures or products. The company specializes in UV light curing systems for industrial purposes, and references to dental applications are based on general knowledge and research within the dentistry field.

Mar 5, 2023 | Blog

Here at Uvitron, we understand first-hand how UV light curing systems have become a crucial technology for many industries. We manufacture our UV light curing systems right here in the USA and deliver them to businesses and industries the world over. The benefits of UV light curing systems are numerous, and the technology has had a significant impact on the efficiency, quality, and sustainability of many industrial processes. Here are some of the key benefits of UV light curing systems for manufacturing and production:

- Speed: UV light curing systems cure coatings, adhesives, and inks quickly, reducing the time required for production and increasing overall efficiency.

- Improved Quality: UV light curing systems cure materials evenly and consistently, leading to higher-quality products with fewer defects.

- Energy Efficiency: UV LED lamps are highly energy-efficient, reducing energy consumption and cutting costs.

- Lower Environmental Impact: UV light curing systems produce less heat than traditional curing methods, reducing the carbon footprint of production processes.

- Increased Flexibility: UV light curing systems can be used on a wide range of substrates, including plastics, metals, and glass, making them ideal for use in a variety of manufacturing and production processes.

- Reduced Solvents and VOCs: UV light curing systems eliminate the need for solvents and VOCs, making them a more environmentally friendly option for many industries.

- Increased Productivity: UV light curing systems increase overall productivity by reducing the time required for curing, allowing manufacturers to produce more products in less time.

- Improved Health and Safety: UV light curing systems eliminate the need for solvents, reducing the risk of exposure to toxic chemicals for workers.

- Increased Durability: UV light cured products are more durable and resistant to environmental stress, ensuring that products last longer and require less maintenance.

- Improved Product Appearance: UV light cured products have a glossy and attractive appearance, enhancing the overall quality and appeal of the products.

Now you know the benefits of UV light curing systems, you can browsw through our systems. After all, the benefits of UV light curing systems for manufacturing and production are clear, and the technology has had a significant impact on the efficiency, quality, and sustainability of many industrial processes. Whether it’s for curing coatings, adhesives, or inks, UV light curing systems are a valuable tool for many businesses and industries across the world.

Sep 17, 2021 | Blog

When it comes to UV light curing, there are a couple options to get the job done: arc lamps and LED. Which will work best depends on several factors. Here, we break down the benefits of UV LED systems and how they are lighting the future of curing.

UV LED Advantages

UV light emitting diodes (LEDs) are semiconductor components that produce light when an electrical current flows through them. UV LEDs are growing in popularity for curing applications for several reasons:

- Because LEDS can be instantly turned on and off, no warmup or cooldown is required. This also makes them more energy efficient since they require less input power and can be powered off between cycles.

- With their cool output, LEDs provide low radiant heat to the product being cured.

- LEDs offer a narrow spectral width with no unwanted wavelengths, as well as improved light uniformity with even distribution over the items being cured.

- There are fewer safety issues with LEDs because there is no fragile glass lamp or filter that could shatter.

- With a life expectancy of more than 20,000 hours and no mercury content, LEDs are also a more environmentally friendly option.

Our UV LED Systems

Our LED curing systems use cool output UV LEDs in four spectral types for high-intensity, rapid curing. They are ideal for applications sensitive to heat or those with a narrow spectral range.

SkyRay LED Curing System

- Curing area: 5 x 5″

- Up to 2200 mW/cm2 intensity at 1″

- Microprocessor control of time and intensity

- Remote control and reporting via PC or PLC

- Integrated lamp head, power supply and controller

SkyRay + Rayven UV Curing Chamber

- Curing area: 5 x 5″

- Up to 2200 mW/cm2 intensity at 1″

- Shielded benchtop curing chamber

- Adjustable shelf height

- Integrated lamp head, power supply and controller

SkyBeam LED Spot Curing System

- Curing area: from 3mm–15mm

- From 900–14,000 mW/cm2 intensity

- Four independent irradiation channels

- Built-in power supply

- Long-life flexible light guides in four wavelengths

Curing Solutions for Every Application

Our team will work with you to find the best curing option for your application. While LED curing offers many advantages, an arc lamp is sometimes a better choice.

Let us know your application details and specific curing requirements using our online form or contact us by phone or email, and we’ll provide a system recommendation. We also offer free sample testing and demo units if required, to ensure the system will meet your needs.